This section covers insulating your camper van conversion. It is aimed mostly at conversions of cargo vans like the RAM Promaster, Ford Transit, or Mercedes Sprinter, but if you are converting another type of vehicle or a trailer, most of the material will probably apply.

Surprisingly, there is no area of camper conversions that is more controversial than insulation. Many schemes have been proposed and used, and they differ greatly from each other, and there is little solid in service test data to say which work and which don’t. I’m going to give my 2 cents on what’s important and give a description of two methods that I like, but you probably want to look around and see all the other schemes.

Insulation — What’s Important?

The things that you typically want out of the insulation you install:

- Good thermal insulator (high R value)

- Able to control water vapor to prevent condensation on the van metal – i.e. don’t harm the van.

- Does not absorb water.

- Able to hold up to the relatively high temperatures and vibration over the long term.

- Not squeaky.

- Not toxic.

- Easy to remove.

Good Insulator: The value of high R value per inch is obvious as there is limited space to install the insulation, but any value from about R3 per inch up is probably workable. If you are going to use the van under really cold conditions, then you want pick one of the insulating materials with high R value per inch — e.g. polyiso sheets or polyurethane spray foam.

Condensation: The control of water vapor and condensation seems important to me. There are sources of water vapor in the van (like cooking and people), and when the outside temperature is cold or even cool, water vapor that makes its way out to the van skin will condense, and this may cause rust or corrosion problems over the years.

While there may be other ways to do it, it seems to me that the most straight forward way to greatly reduce condensation is to use an insulating material that is impervious to water vapor and to cover as close to 100% of the van wall/ceiling surface as possible with it. The idea being that water vapor that cannot get to the van skin cannot condense on it. In addition if the insulation has a sufficiently high R value that the temperature of the inside surface of the insulation remains above the dew point, then you won’t get condensation on the inside surface of the insulation either.

Water Absorption: You do not want insulating materials that absorb and hold water — e.g. no cotton batting or denim.

Vibration and Temperature: The van is a fairly hostile environment for insulation it that there is a lot of vibration, twisting motions, and high temperatures. For example, I would not use Styrofoam (polystyrene) or XPS (extruded polystyrene) near the van skin in that it is only good up to 165F.

Squeaking: Some of the insulating materials are subject to squeaking as the van deforms as you drive it. For example, if rigid foam board is not well adhered to the van skin it can squeak.

Non-Toxic: On the “Not Toxic” front, you want a material that is safe to install and safe to live with over the years bearing in mind that it will be subject to fairly high temperatures and road vibrations. Be careful about materials that might out gas at the fairly high temperatures that the van skin will get to. Fiberglass sheds fibers that are likely not good for you — it will do this during the install, but also during the life of the van as you drive it and shake things up.

Easy Removal: The “Easy to Remove” is a nice feature, but most of the better insulating schemes are going to violate this one. They are more like removable, but with some difficulty.

Vapor Barriers:

Vapor barriers are discussed a lot in conjunction with insulating vans. The van sheet metal itself is a vapor barrier that you have on the outside of the insulation whether you want it or not. I suppose the main question is should you add a vapor barrier on the inside of the insulation? The argument for doing this is that it prevents water vapor generated from cooking etc inside the van from getting into the wall and condensing. I think this makes sense IF the inside vapor barrier can really prevent water vapor from getting into the wall and if there are no rain leaks into the wall cavity. But, on the negative side, if water vapor does get into the wall and condenses, the inside vapor barrier prevents the water from drying out quickly because its trapped between two vapor barriers. The references on home building say that it takes a surprisingly small flaw in the vapor barrier to allow significant water vapor to get through — this makes me think that its going to be very hard to do an inside vapor barrier that is tight enough to keep water vapor from getting into the wall. My 2 cents would be not to use the inside vapor barrier so that moisture that gets into the wall has a way to dry out — but, I’m sure, some would disagree.

Drain Path:

The vans provide drain holes at the bottom of the walls that allow any liquid moisture that drains down the wall to drain out of the van. I think that it makes sense whatever insulating method you use to keep these drain paths open.

Inspection:

I think it makes sense to provide for removal of at least some of the wall/ceiling panels so that a year or ten down the line you can remove the panel and see what’s going on inside the wall and at the van skin.

How Much Insulation Do You Need?

The main reasons for adding insulation include: 1) reduce heat loss in the winter to allow a smaller heater or furnace and less heating fuel usage, and 2) reduce heat gain in the summer so that the van is easier to cool.

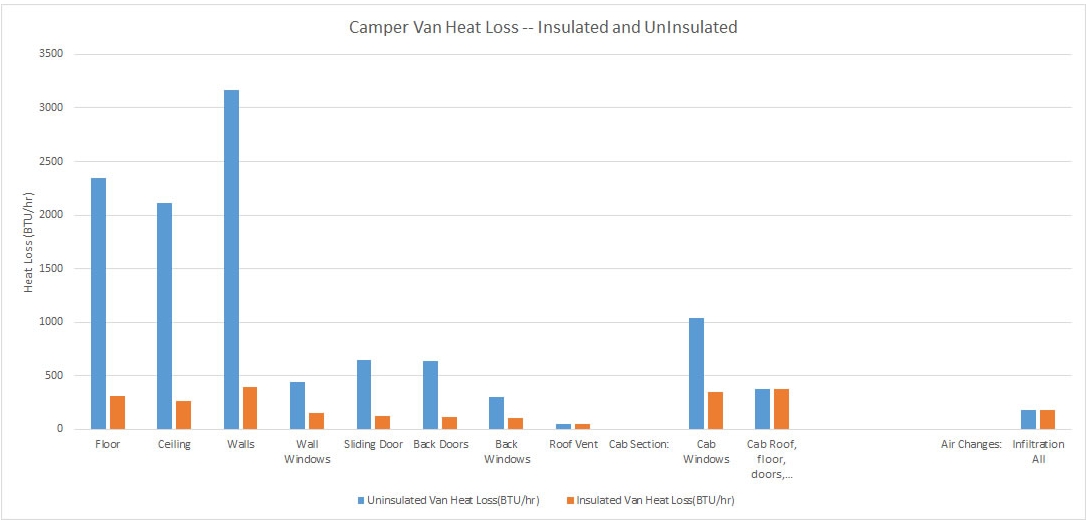

If you want to get into the details of how much heat loss reduction you get for a given amount of insulation, try our calculator you can download here… It allows you to put in various levels of insulation on the floors, walls, ceiling, and also for the windows. It gives an estimate of heat loss you will get for a given combination of insulation and for a given outside temperature. It can be helpful in estimating what size furnace you need and how much fuel its likely to use.

It also provides a chart that shows how much heat is lost through each component (roof, walls, windows, …) so you can see which areas need more attention.

Using this calculator for my van, with 1 inch polyurethane foam insulation all around and Reflectex style window treatments, the calculator estimates that heat loss is reduced by 79% compared to a bare van, and propane consumption for a 32F outside temperature is reduced from 0.18 gallons per hour down to 0.04 gallons per hour.

If you don’t want to use the calculator, as a very rough rule of thumb, you probably won’t end up going too far wrong if you aim for an insulation level around R6 for the walls, roof, and floor.

Insulating Materials

The table below lists the properties of the common insulating materials used in van conversions. There is a lot to be learned by just looking through this table.

| Name | Type | R per Inch | Thickness for R6 | Cost/sqft for R6(10) | Max Temperature | Vapor Barrier? | Absorbs Water? |

|---|---|---|---|---|---|---|---|

| polyisocyanurate (1) | Rigid sheet | 6.5 | 0.92 inch | $0.60 | 270 F | Yes | No |

| Spray closed cell Polyurethane (2) | Spray in place | 6.5 | 0.92 inch | $1.80 (11) | 270 F | Yes | No |

| XPS polystyrene (3) | Rigid sheet | 5 | 1.2 inch | $0.80 | 165 F | Yes | No |

| EPS polystyrene (4) | Rigid sheet | 3.85 | 1.6 inch | $0.55 | 165 F | Yes | No |

| Thinsulate (5) Polyester and olefin | Flexible sheet | 3.3 (12) | 1.8 inch | $2.13 | 200F(?) | No | No |

| EZcool (6) | Thin flexible sheet | ? | ? | ? | 200 F? | Yes | No |

| Aerogel (7) | Flexible sheet is common | 8.3? | 0.72 | $11.50 | 390 F | No | No |

Notes:

(1) Polyisocyanurate: rigid polyurethane insulation, comes in various thicknesses from 0.5 to 2 inch — example…

(2) Spray polyurethane: two bottle DIY kits available, or pro install. Spray to desired thickness. — example…

(3) XPS polystyrene: extruded polystyrene sheets, typically pink or blue, various thicknesses — example…

(4) EPS polystyrene: expanded polystyrene, typically white, various thicknesses — example…

(5) Thinsulate: Polester and olefin fibers with scrim, various thicknesses up to 1 inch ish? — example …

(6) EZcool: 3/16ths thick closed cell polyethylene foam with thin aluminum face sheets on each side — example…, and…

(7) Aerogel: A very low density porous matrix left over after drying out from a gel — example…, and …

(10) Cost — this is the cost per square foot for the exact thickness needed to achieve R6 insulating value. For example, XPS foam sheet costs $21.47 for a 4 by 8 sheet 1 inch thick with an R value of 5. So, Cost = [$21.47) /(32 sqft)]*[R6/R5] = $0.80 $/sqft for R6. The thickness of this (mythical) R6 sheet would be (R6/R5)(1 inch)= 1.2 inches.

(11) The $1.80 per sqft assumes that you actually get the coverage and thickness shown on the packaging. Most people (including me) have found that even with great care to follow the instructions the coverage/thickness comes up short — maybe 20% short in my case.

(12) R value for Thinsulate is based on this page — 0.8 inch Thinsulate is listed as R2.64, so R per inch would be (2.64)(1.0/0.8) = 3.3 per inch. If you have a better source, please let me know. The 3M SM600L that is used in a lot van insulation projects is said to have an R value of 5.2 and is 1.75 inches thick, so R value per inch would be 3.0.

Polyiso sheets and polyurethane spray foam seem well suited to van conversion insulation, especially if the vapor barrier property is desired. They have a high R per inch, hold up to high temperatures, don’t absorb water, act as a vapor barrier. The big difference between these two is the cost and the application technique — the thermal performance is about the same. See below for details on how to install.

XPS polystyrene has many of the same properties as polyiso sheet, but is limited to 165F, which seems a bit low to me for a van in a hot climate right next to the outer skin. EPS is similar, but lower R value, less mechanical strength and somewhat lower cost.

Thinsulate has a relatively high R value per inch, comes in sheets that are flexible and easy to glue in place. It is not a vapor barrier, but does not absorb or hold water. It is said to have good noise absorbing properties, but I don’t know how it compares to (say) spray in foam for noise?

Aerogel is a fascinating material with some very nice properties — it provides a way to get high R values when limited thickness is available, and it holds up to high temperatures. But, it seems (to me) that for van conversions, where there is typically more than an inch of thickness available, that some of the other insulations are more cost effective.

EZcool is a 3/16ths inch thick closed cell polyethylene foam that is covered on both sides with thin alum face sheets. Since the 3/16ths inch of foam core would only have an R value around 0.5, most of the value of this product from an insulation point of view has to come from the reflective face sheets reducing radiant heat transfer. For the reflective face sheets to work on reducing radiant heat transfer, they have to face an airspace — so, you would want to plan your stackup to include an airspace at least on one side of the EZcool. The reflective surface also has to stay reflective over the years if its going to keep its R value. If you can install the EZcool with an airspace and it stays clean, then an R value of about 3.7 might be achieved. It seems to me that a layer of EZcool just inside the van skin with an air layer between the EZcool and the next layer of insulation might be be effective is reducing the radiant heat transfer from the hot van skin inward.

Insulating Schemes

Spray Foam Insulation

Spray polyurethane foam is the method I used on our conversion, so I have the most first hand knowledge of this method.

I picked this method based on its combination of good R value (R6.5 per inch) and the fact that the cured foam is impermeable to water vapor. That is, water vapor originating on the inside of the van from people or cooking or washing cannot penetrate the spray on insulation to get to the van outer skin where it will condense and potentially cause rust. If the insulation has enough R value that the temperature of the inside surface of the insulation is above the dew point, there also will not be condensation on the inside surface of the insulation — this reduces the chance of mold.

On the negative side, the spray foam insulation is more expensive than most (about $400 DIY), and there is a chance (particularly if not done carefully) that the van walls will be distorted as the insulation cures. Also, using the foam can be a bit intimidating if you have never done it before.

There were places that I could not (or did not want to) spray with the spray foaming from the two large bottles of foam. I went back afterword and got some of these areas with Great Stuff canned foam, but there are a few areas that I could not get to or areas with lots of wire runs I did not want to spray. So, this method does not protect 100% of the van skin from condensation.

You may find that there is a commercial spray foam outfit in your area that can spray the van at a reasonable price, but I would make sure that they have had experience in spraying vans successfully and are well aware of how to avoid any distortion of the van walls.

If you decide to do it yourself, this job really puts a premium on doing your homework ahead of time, very good masking of areas you don’t want sprayed, and getting all your ducks in line before you start the spray job as stopping in mid spray is awkward.

There is a very detailed description of how I did the foaming on my van here…

I’m quite satisfied with the results of the spray foaming on my van. The insulation is very well adhered to itself and to the van walls, it insulates well, and there was no problem at all with distortion of the body panels. All that said, if I were doing the job over again, I’d seriously consider the Rigid Foam Panel method described just below. I’ve not had any direct experience with this method, but it looks like it has the same advantages as the spray foam method at a somewhat lower cost and the work required is probably of the same order.

Rigid Foam Panel Insulation

The rigid foam board method that I like uses rigid foam board sheets that are adhered to the walls and ceiling with polyurethane foam in a can (Great Stuff). The sheets of foam board can be cut to cover the larger areas, and then the Great Stuff glues the boards to the wall and is also used to foam the areas around the edges of the foam boards and in the places where there are no foam boards. The foam boards should be foamed carefully around the edges so that water vapor cannot get under the edges and condense on the van walls.

I think its best to use polyisocyanurate foam board insulation. The polyisocyanurate (polyiso for short) insulation board typically has aluminum foil face sheets on each side. The foam itself is usually tan in color. The sheets will say “polyisocyanurate” somewhere on the sheet. A lot of lumber yards carry the polyiso, but they often don’t know it by that name, so ask to see what they do have and look for the polyisocyanurate label. The good things about polyiso insulation are: 1) it holds up to high temperatures (270F or so), 2) it has a high R value (R6.5 per inch), and 3) it is water vapor impermeable.

This is the brand Home Depot carries in some stores.

Here is a very detailed rundown on installing Polyiso rigid foam board on a Ford Transit…

I think that its important to use Polyisocyanurate rigid foam board and not any of the polystyrene based rigid foam boards (eg the EPS and XPS). The reason being that the polyiso insulation is good for higher temperatures.

The 1 inch thick polyiso might be the best choice. It is flexible enough that it can be bent to the curve of the walls and it provides about R6.5. If you need more than R6.5, then two layers of 3/4 or 1 inch is probably the way to go rather than trying to bend or score 2 inch polyiso.

More pictures above from the RD Build on the ProMaster forum. The more I see this method, the more I like it. Another polyiso isulation project from the Promaster Forum.

Also from the ProMaster Forum, here is an example of what I would call a good pattern of GreatStuff on the back of a Polyiso panel. I think that this pattern would insure that you will never get any moisture behind the Polyiso.

If you use the Great Stuff foam to adhere the polyiso to the walls, you will want to have props that you can wedge in to keep the foam board in contact with the wall while the Great Stuff is curing. Once the Great Stuff has cured the the foam board will be VERY well stuck to the wall. You may want to invest in the “Pro” version of the Great Stuff foam applicator — its much nicer to work with than the Great Stuff cans with the plastic straw applicator.

I want to be clear that I’ve not used this polyiso rigid foam board to insulate a van myself — I’ve just reviewed what others have written about it and passed it on here.

If you have used this method to insulate your van and can provide some pictures and description that would be great Contact Gary..

Update: I think that it makes sense to use XPS (extruded polystyrene) for the floor. It is the most resistant to water, and the floor is an area where water from plumbing leaks or van skin leaks or water tank leaks can end up. Its R value is not as good as Polyiso, but it is good and for the floor, the higher water damage resistance is worth taking the small hit on R value. And, the 165F max service temperature is not an issue for the floor.

Thinsulate

Thinsulate is an insulating material developed by 3M that was initially developed for use in clothing. It is composed of very small fibers of polyester and olefin. It normally has a scrim layer on one or both sides to protect the fibers. These fibers do not absorb water, so any water that gets in the wall will not be absorbed by the insulation. But, Thinsulate is not a vapor barrier — that is, it allows water vapor to pass through it. It comes in various thicknesses and weights. It is flexible and can readily be bonded to the walls with something like 3M 90 spray adhesive.

As near as I can tell from the Rockywoods.com data on Thinsulate and the 3M datasheet, it has an R value of about R3.0 to R3.3 per inch.

It was found by the auto manufacturers that Thinsulate has both good insulation and good acoustic properties, and special versions of it are now made for this purpose — e.g. SM600L and here…

Hein on the Sprinter Forum has used Thinsulate in combination with EZ-Cool and Reflectex to insulate his van. EZcool is a thin layer (3/16 inch) of closed cell polyethyene foam with a layer of aluminum on each side. In Hein’s method the EZcool goes in first near the van wall, but not glued to it, then the Thinsulate goes in as the next layer, and then a layer of Reflectex is installed as the inside layer. This post on the Sprinter forum has some details on the installation. Hein also offers a good price on Thinsulate that is well suited to vans — about $1.78 per sqft for 1.5 inch, 600 gm/sm material.

A lot of people seem to be enthused about Thinsulate and this 3 layer method. I’m probably just being obtuse, but its not clear to me why this three layer arrangement is better than a single thick layer of polyiso or polyurethane foam, or how it controls water vapor? I’d be happy to be wrong in my skepticism, so please put a comment in below on why this is a good way to go. I guess that one advantage would be that the EZcool installed at the van skin can act as a radiant barrier to reduce radiant heat transfer into the van — as long as there is a air gap between the EZcool and the Thinsulate. This could be helpful especially for dark colored vans in hot climates.

Other Insulation Schemes

A lot of other schemes for insulating van have been used and proposed. I’m not going to say much about them as, I really don’t have any way to know if they are good or bad.

Fiberglass:

Batt style fiberglass is used quite a bit for conversion van insulation (even by commercial converters). On the plus side, it’s very available and cheap, and fairly easy to install, and its also easy to remove. On the negative side, it readily allows water vapor to pass through it and this promotes condensation on the cold van walls and potentially leads to rust and corrosion. It is also not viewed as a particularly healthy product to install, or to live with long term — all the bouncing around that a camper van does may lead to fibers in the air for a long time.

I have also read stories by people updating a conversion done on an older van in which they removed old fiberglass insulation to find quite a bit of rust on the van sidewalls. I don’t think that this is common, but it does happen.

Most people who have looked into insulation for vans reject fiberglass as a choice, and I agree — I’d go with something else.

Polystyrene (Styrofoam):

I would personally avoid using any of the insulation products that use Polystyrene as the insulating material — this includes the Styrofoam, EPS expanded polystyrene (the coffee cup stuff), and XPS extruded polystyrene foam (the pink and blue stuff at the hardware). The reason is that the maximum service temperature for this material is only 165F, and I think that its possible to get to these temperatures for insulation near the van skin. I found out by unintended experiment that its fairly easy to melt polystyrene based insulation…

Multi-Layer Approaches:

I’ve seen a few descriptions of insulating schemes that use a number of layers of different or similar insulating products on the theory that multiple thin layers achieve a better result and a single thick layer. I have to admit that I don’t see the advantage and it just seems (to me) to add to the work and cost.

If you have a multi-layer scheme that you like and a good line of reasoning for using it, please leave a comment below explaining why you think its better.

Update: This is a report on some testing I did on the most common insulation types used in camper vans…

Update: Sheep’s wool has in the last couple years become a more popular choice. Havlock Wool is probably the biggest promoter of wool. The Havlock site lists a number of advantages for wool. Things like its being all natural, the way it handles moisture, … Unfortunately they don’t provide any test data at all to back up these claims. I have to admit to being a skeptic.

I’ve worked with wool a little during the insulation test mentioned above, and one thing I will say for it is that its so easy on your skin – you can push your face into a bat of it, and feels like a nice wool sweater. On the other side, its difficult to install and I worry that with some of the Youtube installations I’ve seen that there will be significant settling.

If you have a lot of experience with wool, I’d like to hear about it.

Noise Reduction

In addition to lowering heat loss, insulation also provides some noise reduction. There are again a lot of proposals on how to come up with an optimal combination of layers that do a good job of both insulating and reducing noise.

Update: after a few long trips in the van, if I were doing this all over again, I’d probably put more emphasis on noise reduction. Its not that the van is all that loud, but a bit quieter would be nice. I will probably take some time to see what can be on mine at this point — things lie the doors have not been treated and it seems like some of the noise originates from the headliner area.

Figuring Out What Really Works?

Its a bit discouraging that people have been insulating camper vans for decades, and we still don’t seem to have the data that would tell people now starting their conversions what methods are proven to really work well, and which have failed.

It would be nice if we could collect data from people who insulated their vans some time back and are in a position to inspect and take a few pictures of how things are going inside the wall and at the van skin. If you have or are willing to collect such data, please leave a comment or email me so we can arrange to get your story up on the site. This goes for solutions that worked well as well as ones that failed.

Update

November 2020: I did some testing of three common insulations used in van conversions (Polyiso, Thinsulate and Wool). The testing is for a side by side comparison of how these insulation handle moisture and condensation buildup. Have a look!

Gary

July 3, 2015

Thanks for all your help Gary. Very cool insulation test and data, thanks for that!

I’m trying not to overthink things as I begin work on my Sprinter build. My use case will be primarily Colorado or other mountain camping, not a lot of time in the humid midwest or eastern US.

However, I bought the van August 2020 and quickly realized we love it as a ski vehicle as well, which makes me consider drying ski gear on winter trips and the increased vapor issues that may raise.

Still though, in the end I think that between Colorado’s relatively low humidity and remaining vigilant during and after ski trips (keeping the van empty but warm for a day after returning home to drive out residual moisture), I’m probably good as far as moisture/rust issues.

I like your findings regarding polyiso, but I’m inclined to use Thinsulate SM600 for two reasons. One, 🙂 I’ve already purchased 150 square feet of it. Two, I’m just a slight bit concerned about it squeaking with all the rough mountain roads I’m on in the summer.

Thanks for reading this far. My question is this: I already want to use noise dampening in certain areas – the headliner above the cab, wheel wells, etc. So if I put the Kilmat directly on those surfaces, would I then spray the Thinsulate and adhere it directly to the back of the Kilmat?

Thanks,

Chuck J

2017 MB 144 Passenger

Hi Chuck,

I’m pretty sure the Thinsulate will do fine for CO and ski trips – even with some wet gear. I’ve not heard of anyone having a problem with Thinsulate with this kind of use. There will likely be some condensation on the inside of the van skin under the Thinsulate on some nights, but it will dry out when conditions change.

I believe that people are just using the 3M spray adhesive to bond the Thinsulate to both the van skin and the back of the sound treatment.

Hope we get a good ski year!

Gary

re: “I already want to use noise dampening in certain areas – the headliner above the cab, wheel wells, etc. So if I put the Kilmat directly on those surfaces…”

It is worth noting that materials like “Kilmat” attenuate over a fairly narrow frequency range, and almost always down around 100Hz. These materials are not very effective at acoustic noise reduction much above that frequency range. The frequency range of typical “objectionable noise” (e.g.: a diesel engine idling) is more like 250Hz – 500Hz. Typically, a limp mass barrier is the one of the effective ways to reduce transmission of these noises.

Chris Purdue has done extensive testing of many different dampening materials. You can find some of his test results posted on his Facebook group, which is: “The Deadening”

Thanks Elvis,

It would sure be nice to get some real data on what treatments or combinations of treatments actually work for van noise reduction rather than all the conjecture.

Chris’s group looks interesting – will have to spend some time digesting what he has there. Looks like he is also starting a youtube channel.

Gary

(I inadvertently posted this reply in the wrong place below).

I totally agree. I have noticed many times in DIY forums that some people go way overboard with adding heavy low-frequency dampeners to areas where they won’t have much effect. I recall seeing one build thread where a guy added over 600 lbs. of a butyl mat (like Kilmat) to his van!

There is a LOOOOOT of hype and obfuscation (mainly by vendors whose sales are driven by relentless promotion in DIY forums). Thinsulate is an example of that, because although it is effective at acoustic noise reduction in higher frequency range (like wind noise), its ANR drops off drastically at the problematical 250Hz – 500Hz range I mentioned before.

The only real way to get real info is to do the type of controlled testing (for general noise reduction in vans) that only you and I seem interested in doing.

Chris got started with this project several years ago in a ‘DIY mobile audio’ forum. The testing he does is mainly oriented toward reducing bass resonance in powerful car audio systems. He mostly tests ‘Constrained Layer Dampeners’ which are ideal for that purpose, but only have any significant NR effect in that narrow, lower frequency range I mentioned previously. He has posted some of his charts on his Facebook group.

As it turns out, Chris Purdue has tested Killmat.

I captured his chart:

https://i.imgur.com/ZrWTFi3.jpeg

(red line is untreated; blue line is treated)

which shows that it is basically ineffective outside a narrow range of 125Hz-150Hz. On top of that, Killmat is not one of the better performers Chris has tested.

ResoNix is an example of one of the best. Here’s what that chart looks like:

https://i.imgur.com/ai0Dfpi.jpeg

But even Resonix does very little for the typical problem noise range (idling diesel engines, generators, lawn mowers, leaf blowers, etc).

It’s good to learn that you should look for a thermal insulator that has a high R-value. My wife and I are wanting to renovate our home in preparation for the winter and we were wondering how we could insulate our house better. I’ll be sure to tell her that we should look for a thermal insulator with a high R-value.

Hi,

Lots of good resources out there on home insulation. One good good is:

Insulate and Weatherize,

Bruce Harley

More resources listed here: https://www.builditsolar.com/Projects/Conservation/conservation.htm

Gary

I totally agree. I have noticed many times in DIY forums that some people go way overboard with adding heavy low-frequency dampeners to areas where they won’t have much effect. I recall seeing one build thread where a guy added over 600 lbs. of a butyl mat (like Kilmat) to his van!

There is a LOOOOOT of hype and obfuscation (mainly by vendors whose sales are driven by relentless promotion in DIY forums). Thinsulate is an example of that, because although it is effective at acoustic noise reduction in higher frequency range (like wind noise), its ANR drops off drastically at the problematical range I mentioned before.

The only real way to get real info is to do the type of controlled testing (for general noise reduction in vans) that only you and I seem interested in doing.

Chris got started with this project several years ago in a ‘DIY mobile audio’ forum. The testing he does is mainly oriented toward reducing bass resonance in powerful car audio systems. He mostly tests ‘Constrained Layer Dampeners’ which are ideal for that purpose, but only have any significant NR effect in that narrow, lower frequency range I mentioned previously. He has posted some of his charts on his Facebook group.

Gary – FYI:

I ran across this recently while checking updates in the CRRC product directory. https://coolroofs.org/directory

It’s a field applied coating, but is more like paint than acrylic or silicone roof coatings (which are actually liquid-applied membranes). At 8-10 mils nominal desired coating thickness, the coverage per gallon is about five times greater too.

Yet the 3-year SRI is one of the very highest available, mainly because dirt doesn’t stick as easily as it does to conventional roof membranes.

Here’s some info:

https://www.texcote.com/reflect-tec/

https://www.texcote.com/wp-content/uploads/2016/12/aia.pdf

Hi Elvis,

That does look like a good choice for painting roof of van conversions.

Have not been able to find a place that sells it, and it does not appear to be in the Tex-Cote online store. I dropped them an email to ask where it can be bought.

Gary

Based on Tex-Cote’s initial response to my email last week, some of their products may not be easy to buy. But their followup sounded more promising. I’ll let you know.

Reflec-tec has one of the highest long-term SRIs of any “thin” coating in the CRRC directory. But there are many other highly solar-reflective coatings designed for metal roofs and siding, e.g.:

GAF/United Coatings KyMAX

Nutech NXT Cool Coat (Australian company, with US distribution).

Factory-applied Kynar500 coatings for metal roofing/siding have been around for decades, but the field-appliable version was first available almost 10 years ago, ref.:

http://www.kynaraquatec.com/en/product-info/characteristics/

Because the Kynar-based resins are more expensive than acrylic, they tend to be used on higher-end commercial buildings, which may mean large minimum quantities. I’ll let you know when I find sources in the 5-gallon range.

BTW, even Behr has a paint with a high long-term SRI (104): Behr # 4175.

https://i.imgur.com/ChOm1qa.png

It must be a new product though, because that long-term rating has an * (meaning it’s provisional).

Only problem is, I can’t find any info on #4175, and the Behr rep has not yet returned my call.

There is a Behr “Roof Paint”:

https://www.behr.com/consumer/products/specialty-paint/roof-paint/behr-multi-surface-roof-paint

sold at Home Depot:

https://www.homedepot.com/p/BEHR-1-gal-White-Reflective-Flat-Multi-Surface-Exterior-Roof-Paint-06501/100164524

seems is a different model number (#6501, which is not in the CRRC directory). My guess is, this paint has a fairly high SRI, but almost certainly not exceptionally high.

In comparison, even a typical OEM automotive white paint *should* have an SRI of somewhere around 80-85. So on a white van, there are limited gains available with even the highest performing coatings (but every bit helps).

With most “regular” paints (not specifically designed to have high SRI), a flat finish will have higher SRI than gloss, because gloss usually has lower thermal emittance than flat.

Hi Gary, regarding a multi-layer scheme you asked about, I might be a source for you.

Installing polyiso boards on all surfaces except back and slider door.

I allowed room for 1.5″ Thinsulate covering all surfaces except floor. The plan is to take advantage of Thinsulate’s excellent sound absorbing qualities. It helps that it offers additional insulation as well.

All doors and vertical door framing have Thinsulate. Quite a bit over the cab area between steel roof and one piece molded lining being careful to allow easy access to the front roof light I wish were not there. In that same area added Thinsulate to the left and right wall pockets next to the upper cab shelf. Surprisingly it swallowed a lot of Thinsulate.

Floor will be 1.5″ Polyiso + 1/2″ horse stable/gym rubber then 1/2″ plywood. The horse stable rubber sheets come in 1/2″ and 3/4″ from Tractor Supply.

I did not do a before noise measurement but remember how painful it was for wife and I to have a conversation or even hear the radio prior to adding anything. Goal is to be as quiet as a quality minivan.

Will let you know.

Santiago

Hi Gary,

Question on polyiso board SIDES when installing using Great Stuff foam as adhesive.

Gluing 1″ and 2″ boards and sealing around edges – no issues.

Board SIDES not fully covered by Great Stuff foam – bad practice ?

The foil faces are practically impermeable but the foam sides not so much ?

While most board SIDES are immersed when beading, thicker ones, 2″, not easily immersed. How critical is having partial SIDE exposed to vans’ interior moisture. I imagine that can be a pathway to the interior especially if not foiled faced on both sides.

Thank you.

Santiago

Hi Santiago,

Polyurethane foam spray foam (closed cell) is used a lot in home construction with no vapor barrier in that (even without a foil face) it has a low water vapor permanence. The Polyiso sheets are the same kind of foam, so I’d guess that having the sides of the ridid polyiso sheets just foamed with Great Stuff (also polyurethane foam) is probably OK from a water vapor point of view.

Open cell foam is much more permeable to water vapor, but don’t think its used in vans much.

It does seem important if you want a really good insulation job, that carefully foaming in the areas around the rigid polyiso panels with Great Stuff is important both from a condensation point of view and from the point of view of reducing high thermal conductivity areas that are not insulated.

But, I’m not an insulation physics guy — so, I guess, ask around.

Gary

Thank you Gary. Am installing polyiso as we speak but wanted to better understand its’ use when subjected to a typical moisture laden van interior.

A little more research told me that what gives a polyiso foam board extremely low permanence is the foil facing. Both sides faced is ideal.

With foil facing the permanence is 0.03 perms – this is Class 1 (impermeable vapor retarder).

The polyiso itself without facing is 2.8 to 4.5 perms – this is Class 3 (permeable vapor retarder). Thank goodness the board edging surface area is quite small compared to the board surface covered with foil.

It would not be good idea to use a board with just one surface covered with foil, nor eliminating the foil facing itself.

Thanks again,

Santiago

Overall, this site is a terrific resource for DIY’ers considering upfitting a van.

But you omitted any mention of 2-part pourable cavity-fill foam, which is available in both rigid and flexible types. This type of foam is the closest thing to the foams used by auto manufacturers and also sold in small kits to collision repair shops.

Also, I thought I saw a mention somewhere that mono-component spray foams like ‘Great Stuff’ are closed cell. That’s not actually correct, because ‘Great Stuff’ has a relatively low percentage of cells that are closed (typically not much over 50%-60%). Some other brands of mono-component spay foam (e.g.: Loctite, DAP) are better, but only 2-component field-applied foams exceed the 90%-95% threshold. In comparison, manufactured foams like Tuff-R or Thermax are more than 99% closed cell… basically only the edges have some open cells.

BTW, the concern about polyiso foams having reduced R-value at low temperatures is a concern that isn’t applicable to polyiso sheathing like Thermax, Tuff-R or AP-Foil.

FWIW, most (if not all) of the fiberglass batt insulation sold in home improvement stores is formaldehyde-free. And there is a big difference between the handling/cutting/fitting characteristics of traditional fiberglass batts compared to the commonly available semi-rigid mineral wool sheets/slabs. But a few years ago, Owens-Corning introduced a new type of batt, “Pure Safety” that has the thermal & acoustic performance and safety of mineral wool, with the flexible handling characteristics of fiberglass batts. It’s sort of the best of both, and an excellent choice to fill the deep structural cavities that are mostly open/accessible.

Just some minor issues… but keep up the good work.

Hi Elvis,

Thanks for the comments.

I’ve not seen the 2 part liquid foams used for RV or van insulation — it seems like it would be awkward to use in that you would have to provide a cavity for the foam to fill? I did use the 2 part urethane foam to insulate my van, and found it to be a good way to go.

https://www.buildagreenrv.com/our-conversion/our-conversion-insulation/

I’ve always heard the Great Stuff foam being described as closed cell, and that is also what the manufacturer says. Do you have a reference that shows the percentage of closed cells for the various foams you mention. I kind of like the Great Stuff Pro as its fairly cheap and available in lots of places.

The Building Science Site has a good article on testing of the polyiso rigid sheet foam that shows a degradation in R value per inch for cold conditions for all the rigid foam sheets they tested. They don’t mention any of the brands being immune from the R value loss in cold temperatures.

https://www.buildingscience.com/documents/information-sheets/info-502-temperature-dependent-r-value.

If you go through the test results, for a van situation, its not really a problem for van insulation. The cross over point where XPS gets better than polyiso is about -20F. Polyiso also has the advantage of a high service temperature, which can be important for hot van skins in hot sunny weather.

Gary

The 2-part liquid cavity fill foams are not awkward to use to fill structural boxes down near the floor, which both the Transit and Sprinter have. It can also be used to fill the vertical channels that otherwise require stuffing (for those who insist on using Thinsulate). Of course the openings below the pour point have to be closed off with tape. etc. The easiest way to ensure no excess foam spreads outside the intended area is to use plastic containment bags… which also prevents it from sticking (a concern for some people). The bags can be simply trash bags, but there are other alternatives that have higher acoustic absorption.

People may refer to Great Stuff as being “closed cell” but AFAIK the manufacturer does not. They do list the closed cell percentages for the pro versions in the TDS (available at Homedepot.com or greatstuff.dupont.com):

GREAT STUFF PRO Gaps & Cracks Insulating Foam Sealant – Closed Cell Content, ASTM D2856, 80%

Great stuff Pro Window & door insulating foam sealant – Open Cell content, ASTM D6226, <88.00%

The stuff coming out of the older-style straw dispensers is not at that level… something to do with the physics of how the foam forms in a tube downstream after the flow valve, vs. how it forms when exposed to air only when it comes straight out of a flow valve. Hard to express, but I'm pretty sure the manufacturer's engineer wasn't BS-ing me.

Most true closed cell foam is much higher than that. While any of this stuff will work fairly well, there are better alternatives, namely, Loctite TiteFoam and DAP Draftstop 812.

Building Science Thermal Metric Study

https://www.buildingscience.com/documents/special/thermal-metric

did not originally measure the same type of Polyiso as Thermax. There are many different 'flavors' or polyiso and PU foam, with properties that vary depending on the exact chemisty. Thermax is a top-of-the-line product.

Only Thermax is specifically rated by the manufacturer to have higher R-value at low temperatures. Here's a chart:

https://i.imgur.com/xyzIfRC.png

You can find this in a manufacturer publication on Thermax applications. I'll look for the title/link later.

My *assumption* (which the manufacturer rep will not confirm) is that Tuff-R is the same, because Tuff-R is basically Thermax without the Class A fire rating.

I mis-spoke about J-M AP-Foil not having the drop-off in R-value. I honestly have no idea about that, but I wouldn't use that as long as either Thermax or Tuff-R is available locally. I would avoid the R-Max foam sold in Home Depot stores west of Ohio… it's a second-tier product.

Here’s the publication that has the Thermax low-temp R-value chart referenced above:

“Tech Solution 538.0: Understanding Mean Temperature Phenomenon for Polyisocyanurate Insulations”

A similar chart also appears in

“Tech Solution 127.0: Understanding Roof Insulation Performance in Cold Storage Buildings”

Seems the PDF upload ikn my previous post did not work?

So here’s a link:

https://www.pdfhost.net/index.php?Action=DownloadFile&id=5840c11595ac4c0a7cba00e9a2a36e73

The bottom line is, all Polyiso is not anywhere close to the same. Field-applied spray foams are about the worst, because it’s more difficult to consistently get exactly the right mix. My belief is that 2-part pourable cavity fill foams tend to be better than 2-part spray foams *IF* the user is very careful about measuring & mixing the two parts. Manufactured foams tend to be the best, because they have much better control over both the mix and the environmental factors.

Hi Elvis,

Well that’s certainly interesting on the Thermax.

I always read manufacturers data with a grain of salt — there is a tendency to not exactly lie, but to tell the story from a limited point of view that favors their product.

They talk about an actual test they did using a wall that was a combination of Thermax and rock wool, and while I can see the point they are trying to make, its not a very straight forward way to do the testing. Then they talk about the new facility aimed at testing insulation under real world conditions (developed with assistance from the Building Science site people), but don’t say that their data on Thermax is actually based on testing in that facility. I looked on the Building Science Site for info or test results on Thermax, but could not find anything. I would think that if the Thermax performed as well as they show at low temperatures that they would brag about it more.

I guess I would now lean toward using Thermax, but I wish their data could be confirmed by an unbiased third party.

The other very interesting thing in the same article is the performance they show for SPF (spray polyurethane)in Figure 2 shows it having highest R value per inch and the R value does not drop for low temperature — it actually goes up.

If this is a universal trait for SPFs, it seems like an advantage to SPF.

I looked for R value vs mean temperature data for CorBond spray PU foam (they have a big presence here), and could not find anything. Again, it seems odd that if it has this characteristic that they would want to brag about it.

I used a two large bottle kit from HomeDepot on my van and I’m wondering how closely it matches their SPF graph.

Anyway, interesting stuff.

Gary

From that PDF, here’s the gist of it:

…some polyiso insulations that “contain an insulating gas that enhances the R-Value of the material are known to exhibit the ‘mean temperature phenomena.’ When the gas condenses to a liquid within the insulation at lower temperatures, the R-Value is slightly reduced as the condensed gas can no longer influence the R-Value of the insulation.”

and…

“…the type of polyisocyanurate foam insulation in the BSL Thermal Metric Project is only roofing Polyiso insulation, which is significantly different

from THERMAX…polyisocyanurate foams have a wide range of property variations as a result of varying/different proprietary formulations used by each manufacturer and for different grades of foam.”

This is the relatively new GREAT STUFF “Smart Dispenser”

https://www.greatstuff.dupont.com/products/smart-dispenser.html

https://www.lowes.com/pd/GREAT-STUFF-Smart-Dispenser-Gaps-And-Cracks-12-oz-Spray-Foam-Insulation/1000673769

This basically mimics the functionality of the metal “pro-grade” guns (plunger valve is at the outlet of the tube). It also cost quite a bit more than the cans sold at Home Depot that have a more conventional ‘straw’ dispenser.

On Lowes.com, this version of GREAT STUFF is listed as R-3.7 per inch.

The GREAT STUFF PRO (gun grade) TDS lists K-factor: 0.26, which equates to R-3.85 per inch. ref.:

http://msdssearch.dow.com/PublishedLiteratureDOWCOM/dh_0943/0901b80380943321.pdf?filepath=styrofoam/pdfs/noreg/179-07323.pdf

DAP Draftstop 812 is rated at R-5 per inch, making it the highest of any mono-component spray foam. (AFAIK). ref.:

https://www.dapspecline.com/media/1071/dap-812-sellsheet-2017.pdf

Draftstop 812 also has considerably lower water absorption than Great Stuff too, probably due to the higher closed cell content.

Another option for filling smaller voids (especially overhead) that can be problematical for 2-part pourable foam:

HandiFoam E84 II-16

“HandiFoam E84 II-16 is a two-component low-pressure spray polyurethane foam (SPF) specifically designed to provide an easy and reliable touch-up and repair product. Other applications include, but are not limited to, sealing and insulating small voids and areas, bath and hot tub insulation and refrigeration truck and trailer repair. ”

https://www.handifoam.com/product/handi-foam-e84-ii-16/

https://www.handifoam.com/wp-content/uploads/A16542-HandiFoam-E84-II-16-4.2018-1.pdf

Gary – another way to look at this is which type of foam predominates in of recreational coolers (especially the high-end brands), reefer vans & trailers, and walk-in coolers. It’s sure not XPS foam. PU injection foam owns this.

I think the solution to the puzzle is that he BSL study that showed polyiso had lower R-value at cold temps is an old study, and according to the white papers, pertained to the type of polyiso used in built-up roofs, not foil-faced Polyiso sheathing.

I am about 75% sure that Tuff-R is essentially the same as Thermax, but without the fire-resistance rating. Home Depots in most of the eastern US stock Tuff-R, but you can buy Thermax just about anywhere from building supply warehouses that mainly sell to contractors.

BTW: Here are three examples of the type of pourable foam (in pressurized cannisters) can be gun-applied:

https://www.handifoam.com/product/handi-foam-slow-rise-low-pressure-pour-place-polyurethane-foam-pip/

https://www.handifoam.com/product/handi-foam-channel-fill-low-pressure-pour-place-polyurethane-foam-pip/

https://www.handifoam.com/product/handi-foam-channel-fill-ef-low-pressure-pour-place-polyurethane-foam-pip/

But all of these cost a lot more than the pour foam that comes in jugs that you have to mix & pour yourself. In fact, only the 2-part pour foam from US Composites in Florida is in the same price range per cubic foot as Tuff-R from Home Depot (which also has foil facers on both sides). I use solid blocks of manufactured foam like Tuff-R in any large cavity where it’s feasible, especially for any of the large openings in the front.

Tradeoffs.

re: “CorBond spray PU foam”

I had not checked the specs on that lately.

J-M’s polyiso/PU foams always seemed to lag a bit below Dow in the past, but Corbond’s specs:

https://www.jm.com/content/dam/jm/global/en/building-insulation/Files/BI%20Data%20Sheets/Resi%20and%20Commercial/JMCorbondIII-ds.pdf

…might make me a believer.

They state that Corbond is R 7 per inch, which is nothing new, a lot of others claim that, but if you read their fine print, it’s usually the *initial* R-value.

But J-M rates Corbond R7/in using ASTM C518 (the *aged* R-value), the same standard Dow uses for Thermax (R 6.5 per inch… with facers!).

It’s *really* hard for me to believe they’d achieve that in most real-world applications (because there’s just no way to make sprayed-on foam as uniform as sheets produced in the controlled conditions of a factory), but it’s still impressive, and certainly a step above the 2-part spray foam kits (e.g.: Touch-n-Foam, Frothpak, about R5.5/in max) sold in Lowes/Home Depot!

And its purple too 🙂

Gary

Gary

Here’s one of the most recent (3/2015) articles I found about polyiso R-values being lower than the product manufacturers’ published values.

http://docserver.nrca.net/technical/9992.pdf

It describes a test of six 2-inch-thick, permeable-facer-sheet-faced polyiso-cyanurate insulation obtained from NRCA contractor members.

That’s not the same polyiso as foil-faced sheathing; it is higher density (usually about 4-lb./CF) and has a fiber facing. I actually have a stack of this stuff (4-inch thick) in my garage. Most of this type of foam is rated less than R-6 at 75°F.

The decrease in R-value is a result of condensation of the gas in the cells of the foam insulation, which is dependent on the ‘blowing agent’ used to manufacture the foam. These blowing agents possess different thermal and condensing/boiling points. Depending on the temperature in the foam cells some blowing agent may partially or completely condense out leaving only air as the insulating “gas” in the cells.

This and other less recent articles are by Mark S. Graham, Vice President of Technical Services at NRCA (Nat’l Roofing Contractors Assoc.).

So, when Dow states this:

“Not all polyisocyanurate foam insulations exhibit the same R-value relationship with temperature. DOW THERMAX™brand polyisocyanurate Insulation gains R-Value at all lower mean temperatures, unlike roofing polyisocyanurate insulations that have been reported to lose significant R-Value in third party studies. This is because THERMAX™ Brand Insulation is different from other polyisocyanurate foam insulations in both the core properties and the facers.”

…I think it’s credible, given that the insulation properties of any given foam depend greatly on how small (or fine) the cellular structure is, and the characteristics of the gas inside those cells.

…and it’s also good to know that polyiso’s close counterpart – 2-part polyurethane foam – evidently does not have reduced R-values at lower temps either.

Hi Elvis,

I’m sort of inclinded to believe the DOW story on Thermax — at least to some extent, but it would be nice to see some third party test data.

Just out of curiosity, I called some places here to see if I could get Thermax. Did not find anyone who stocked it. The place in town that is best about ordering in special products thought they might be able to get it, but only in “unit” quantities (which I think is about 40 sheets).

One thing I’d point out to anyone following this is that they are showing R value results for the mean temperature of the insulation. When you see a decreased R value for 25F, there is a tendency to think that 25F is not really that cold, but the 25F is the mean temp — if the inside temp is 75 F and the mean insulation temp is 25F, then the outside temp is likely -25F — even in very cold Montana, we have years when we never get a temperature that low — not even for an hour.

Gary

As one example, Thermax is available in St. Louis at Negwer Materials. Maybe you are in one of the parts of the country that’s far from one of the plants where Thermax is manufactured?

It really depends on the part of the country. Several years ago, Dow shut down the plant in Missouri that manufactured Thermax & Tuff-R, and that’s when local Home Depots switched to the cheaper R-max brand.

Thermax is also sold online, https://www.awarehousefull.com/dow-thermax-sheathing/

but of course shipping 4×8 sheets isn’t exactly feasible. Also, even the sheets in the stores tend to get banged up, so I;d want to pick my own.

Super-Tuff-R is stocked at Home Depots in Ohio and points east.

https://www.homedepot.com/p/Super-TUFF-R-1-2-in-x-4-ft-x-8-ft-R-3-3-Foam-Insulation-268413/100322369

My *guess* is that J-M AP-Foil probably does not have the low temperature R-value fall-off, but unless J-M confirms it, it’s just a hunch.

I’m getting ready to purchase my van; in the meantime I’ve been trying to decide what things are better.

Any thoughts on sheep wool (such as what Havelock is selling) for insulating?

Hi Brenda,

I guess you could say that van insulation could be divided into 3 classes:

1- Insulation that is not permeable to water vapor — eg Polyiso sheets or sprayed urethane foam.

2- Insulation that is permeable to water vapor, but where the insulating material does not itself does not absorb water — eg Thinsulate

3- Insulation that is permeable to water vapor and also capable of absorbing water vapor — eg Wool, recycled bluejeans.

I favor the 1st category on the basis that if you have an insulation layer that does not let water vapor pass through it, then the water vapor cannot pass through the insulation and condense (or freeze) on the cold van skin. An additional big advantage is that the inside surface of the insulation stays warm and does not normally go below the dew point of the van air, so no condensation anywhere. Given all the bad effects of condensation (rust, mold, …) I thing this is important.

My 2nd choice would be category 2 (permeable, but not water absorbing – eg thinsulate). This is just based on the idea that

insulation that does not absorb water from the air and does not provide a place for water to accumulate seems like a good thing. The proponents of Thinsulate type materials is that the insulation will not absorb water and that if there is sufficient air flowing through the insulation the air (when its dry) will pull any accumulated moisture out of the wall.

Category 3 would be my least favorite for the reasons stated above.

People who have used wool have reported a low level wool smell over time. Maybe not a big deal.

I’m not an expert on insulation physics, but just reading the tons of insulation opinions out there, I’ve come down to using Polyiso sheets (as described above) or the spray polyurethan foam insulation.

Thinsulate has a lot of followers, and I’ve not heard any disaster stories about it.

Sorry to not be much help — its a tough subject to navigate through.

Gary

Hi Gary,

Thanks for all the great info. I’m just getting started and would like your thoughts regarding the ventilation ports at the rear of each wheel well. Did you somehow seal off these vent holes or leave them in place?

Hi Teresa,

As far as I can recall, I left them open and functioning.

I think they are vents that make it easier to close the sliding door by preventing an air pressure bump as the door closes.

I think most people leave them open.

Also, make sure not to block any of the drain holes at the bottom of the walls.

Gary

Insulating your van is the best way to keep warm in cold weather. There are many types of insulation options available so, before you begin the work, keep in mind, that starting with the roof is best. RV Roof Magic is the obvious choice as it is highly reflective which reduces surface temperature and cooling costs.

Lauren is associated with the RV Roof Magic. Normally I would remove comments companies marketing their products, but I do think its worth considering these kinds of roof coatings — just be sure to do your homework on whether such a coating will help in your circumstances.

Admin

I checked this out a few months ago. The comments on Amazon were very detailed and enlightening – and very critical. The product has since been de-listed. Many complaints about being lumpy and semi-solid in pail after just being stored three months or less. Lots of complaints about uneven application. Failure to adhere to some roof types. Primers are required some of the time. And must be of the right type and properly applied. Intrinsically this is likely a good product. My guess it is best applied by a professional under the ideal conditions. Yet, professionals don’t use the product that I talked to or just a cheaper generic version. I find their website very simplistic and over hyped.

Thanks Bob

Gary

Going to have my van sprayed with insulation. Do you think applying a thin layer of foil backed bubble insulation with 3M spray to the van walls with help keep the van walls from rippling when the foam cures?

Hi Jenny,

I’d say no as long as the spray outfit has done vehicle spraying and knows the precautions to take to avoid distortion of the walls.

I’m not sure that adding the layer of the bubble insulation would be risk free. Will it stay well adhered to the van skin over time? It can get over 160F at the van skin, will the bubble stuff hold up to that? I think you are better off finding a spray foam place that can do it right.

Another option, if you are concerned about the possibility of distortion, would be to use rigid polyiso insulation adhered to the van skin with Great Stuff urethane foam. Its explained a bit on this page https://www.buildagreenrv.com/design-and-build-information-for-camper-vans/install-insulation/ under the heading Rigid Foam Panel Insulation.

Gary

Gary

Hi Gary, do you think a silicone mat such as what is used for baking or something like this might be useful as a 1st layer for preventing conduction of heat into a van or even a silicone roof type paint? https://www.amazon.com/Silicone-Rubber-Sheets-Medium-Hardness/product-reviews/B078Z22PCR/ref=cm_cr_dp_d_hist_5?ie=UTF8&filterByStar=five_star&reviewerType=all_reviews#reviews-filter-bar

Hi Steven,

Silicone has about the same thermal conductivity as wood, so, it would help a bit thermally, but not nearly as much as the same thickness of insulation.

Thermal conductivity of materials: https://www.engineeringtoolbox.com/thermal-conductivity-d_429.html

Gary

Gary – that chart in the link you posted is beyond my non scientific brain but I did notice that it included silicon but not silicone. Hot pot trivets 1/16″ thick and oven gloves are now made from silicone because they allow picking up very hot pots, up to over 400 degrees without getting burned. https://www.taychem.com/2018/07/03/why-silicone-is-heat-resistant/

Hi,

The numbers in the table are just thermal conductivity — the higher the number, the more heat they conduct and the worse they are as insulators. So, the silicone rubber is about 0.2 and a good insulator is about 0.02 or about 10 times better as an insulator.

The silicon cast resin in the table is same as silicone rubber.

If you did not have an insulation layer in your floor stack up (the polyiso), then I’d say a layer of the silicone rubber would help as a thermal break, but since you do have the layer of actual insulation, adding a thin layer of silicone rubber would have very little effect on heat transfer through the floor.

Gary

I get it now. Thanks for the explanation.

I saw a Youtube video the other day on van insulation with the recommendation not to insulate if you plan to be in very hot weather primarily, the reason being that no matter what you do, the van will get hot and the insulation will keep the van hot long after the air cools down. ( 17:14 https://www.youtube.com/watch?v=FVk8csC6OiM – This sounds ridiculous to me unless the insulation itself holds onto heat. Unlike a stucco house the metal van body should cool off very quickly and the hot interior air can be quickly vented outside with a fan allowing cool air to replace it. What do you guys think?

Hi Steve,

I agree with you — it sounds ridiculous.

Its important to have some form of forced ventilation in the van — like a MaxxAir or Fantasic fan in the ceiling. This will quickly cool the van once the outside air temperature drops. And, during the day, the insulation plus some forced ventilation will keep the van temperature close to the outside air temperature. Without insulation, the temperature inside the van will be well above the outside air temperature if the van is in the sun.

If its a hot climate where air conditioning is necessary, the insulation will greatly reduce the load on the AC and allow a smaller AC unit to cool the van.

Insulation also reduces the noise level in the van to a reasonable level — without it, the van noise level will be very high.

Gary

Auralex Tubetak Pro Liquid Adhesive sold by Home Depot is made to attach PolyIso sheets.

Just a thought…

Hi,

Don’t have any experience with this adhesive, but one negative is that its max service temperature is listed as 158F. On a hot sunny day with the van in the sun, the van metal temperature will exceed this.

A lot of people have used Great Stuff urethane foam to attach Polyiso successfully, and I’d be inclined to stick to this method until there are some reports from people who have used the Tubetak successfully.

Gary

Dear Gary,

FIRST: BIG THANKS for your website, knowledge, and willingness to share your extensive experience. I’ve been studying (and nerding out on) your methods and links for almost 2 years as I’ve planned our van, which we now have and are starting the build.

My question concerns insulation, especially Great Stuff.

I’ve read quite a bit on car repair and modification blogs/sites–and seen some scary pictures–about how GREAT STUFF corrodes and rusts metal from the inside out in the long run.

So, for insulation we are planning maxing on polyiso where we can, and filling gaps, ribs, and hard to reach place with Thinsulate.

“DeepRed”(http://deepredmotorhome.com/insulation.php) used SIKAFLEX 221 to attach his polyiso panels.

It’s made for autos, is non-corrosive, & temperature stable. So I’m thinking about using that.

Do you have any experience/knowledge with the Sikaflex 221 or info about corrosion with Great Stuff?

I’ve used GS plenty in home reno applications, so I’m comfortable working with it. But, I do plan on keeping the van for a looong time, so I don’t want to have rust issues.

Thanks in advance,

Janet aka “JansVans” on Promaster forum.

Hi Janet,

I’ve not heard of any problems with GS causing metal corrosion, and not seen any on my 4 year old conversion. I would like to see the links you mention if you can find them again.

I used Sikaflex in a couple places on the conversion, and it worked well. But, not sure is was the 221. They do certainly have a good reputation.

How well it would work for securing insulation panels, I just don’t know. It does seem like you would have to use a lot of it to insure that water vapor does not have a path into the area behind the panels.

I like the GS as the adhesive because you can put generous beads of it over the back of the insulation panel in a grid pattern, and when you place it against the van wall it expands enough to completely seal the back of the insulation panel so that water vapor cannot get behind the panel and condense there — potentially causing rust or corrosion over time.

I like using GS around the edges of the insulation panels for the same reasons. GS is also a very good adhesive, so no worries about it coming loose over time or squeaking.

As you have no doubt noticed there are a lot of insulation schemes out there, all with there strong supporters. Not a lot of hard data out there to support any of the methods. I do keep an eye out for people reporting rust or corrosion problems with insulation on vans, and there really are not that many horror stories — I’ve found a couple stories on problems with fiberglass insulation (which would probably apply to any water vapor permeable insulation), but that’s about it.

Gary

Thanks for the speedy reply. I’m back in the Great Stuff camp. Sorry to throw a fly in the contentious insulation ointment.

I spoke today with a technical assist guy at Dow re: GS. He said: 1)GS is not corrosive once it cures; 2) but, it does absorb water. I think the car blogs I saw that used GS and had rust issues, used it where it was exposed to water, hence the rusting.

Dow says the “window and door” product is a softer and white version of the “multipurpose black”, which is advertised as appropriate for RV and marine uses. All the GS products are essentially the same formulation, with variances in expandability and softness (in the case of window and door) or color (multipurpose black).

Unfortunately, it appears that “window and door” and “Multipurpose” are not available in the PRO sizes which fit on the ProGun. I ordered a Pro Gun and pro cans of Gaps n’ Cracks (and some gun cleaner.).

I’m planning to use 1″ polyiso boards, doubled up where possible on the walls and doors. 1″ on ceiling, 1″ under factory floor.

Thanks again for all your help.

I would suggest using 2” polyiso on the sides. Fits perfectly and requires no doubling up and double cutting

Hi Janet,

Good to hear that Great Stuff answers the phone and has some technical support — seems rare these days.

The Pro is available in the Window and Door version — Amazon has it.

I believe that while urethane foam (which is what GS is) has a low permeability to water vapor — much lower than fiberglass or thinsulate, so while its not vapor impermeable, it will let a lot less water vapor through to the van skin that other insulations (I think:)

You will want to use the spring strips of wood to push the Polyiso against the wall until the GS cures.

Gary

My question might fit better on the more-recent posts about thermal bridging, but it looks like comments aren’t enabled there.

You tested two options for insulating ribs: Thinsulate pulled into them, and foam on top of them. What about spray foam, such as Great Stuff, inside of them rather than Thinsulate? Would you be worried about the foam deforming the outside? Couldn’t you avoid that problem by leaving enough holes open so the foam could expand out of them somewhat? I know Great Stuff says it’s not for filling closed cavities, so maybe this is a dumb idea. But it seems like it would work. Thoughts?

Hi Brian,

I think you could use Great Stuff to fill the frame cavities. I would use the low expansion stuff they make for windows and doors. Don’t think you would see any deformation of the sheet metal. Great Stuff cures from moisture in the air, so the cure time for foam sprayed into the frame cavities might be quite long — you could mist into the frame cavity with water before foaming to get a faster cure.

I don’t think that the heat loss difference between foam and Thinsulate would be much for this case. I think the frame webs are responsible for a lot of the heat loss and no matter what kind of insulation you use in the cavities, there will still be the thermal bridging caused by the metal frame webs.

Insulating over the top of the frames with (say) a thin layer of Polyiso is likely to work better in that you won’t get the thermal bridging. But, understand that not all are going to want to mess with insulation over the frames.

I do think that Thinsulate is a good choice for the frame cavities in that its pretty easy to install, it does do some good, and its easy to take out if you later want to run a wire through the frame cavity. But, kind of a pain to just order a little of it for the frame cavities.

I enabled comments on the bridging page (just forgot to check the box earlier), but might as well leave these here.

Gary

Hi there, thank you for the wealth of information you provide on your site. My question is this, I had some LPDE plastic lying around and I figured, why not use it up to insulate some of the ribs of the van…? Then realized that its upper temp is 176 degrees F and maybe that wasn’t such a smart idea. Do you think that it will withstand the summer heat levels my van is commonly subjected to, around 90 to 100 degrees F ambient…? What would happen to it at temps higher than 176 degrees? Will it melt, combust, what? I’m trying to decide if it’s worthwhile pulling it all out. Appreciate any advice you can give.

Hi Beth,

Good question – not sure I have a good answer 🙂

My first thought was that LDPE might not be a very good insulator, but one place lists it as R3 per inch, which is not bad.

At least one place lists the max service temp as 90 to 100C (194F to 212F), so maybe the 176F is on the conservative side?

You could use one of those IR temperature guns to actually measure the temperature of the van metal skin. If you don’t have one already, they are cheap and useful for a lot things. https://www.amazon.com/Etekcity-Lasergrip-774-Non-contact-Thermometer/dp/B00837ZGRY/ref=sr_1_4?ie=UTF8&qid=1524066462&sr=8-4&keywords=ir+temperature+gun&dpID=41xO8jWPMwL&preST=_SY300_QL70_&dpSrc=srch

The surface temperature will depend a fair bit if your van is white or a darker color — dark running hotter.

Not sure what happens if the LDPE gets to hot, or whether it produces anything toxic.

I guess if it were me, I’d measure the surface temps on a hot day in the sun and go from there — I’m guessing its probably OK.

Please let us know!

Gary

Thanks Gary!! Well my van is white. It seems like that makes a big difference from all what I’ve read. I’m sure that melting LPDE would not be entirely benign but I’m going to wing it and hope that surface temps don’t get that high. Unfortunately I can’t wait for the summer to take readings as I’m going to cover up this whole mess with ply and carpet hopefully well before then. I found a website where someone tested surface metal temps of darker vs. lighter Camrys (here if you’re interested http://www.tom-morrow-land.com/tests/cartemp/) and none of the surface metal temps were higher than 150 F (and that was for the black/dark cars). I also didn’t use it throughout the van just in a couple spots where I was being impatient/miserly.

Gary,

Thank you for such a great blog and write ups. I have a 159″ PM and have installed the floor with 1″ polyiso w/ 1/2″ ply following your lead (but not filling in the valleys).

Going to go with rigid 2″ polyiso boards for the sides and 1″ for the ceiling. Just wondering what you think is the best way to do the ribs? Run wires first? Thinsulate after?

Thanks,

Kevin

Hi Kevin,

I think you would be better off to work out where your main wire run areas are going to be and not insulate them at all, or wait until after the wires are run.

On mine, most of the wires that need to go up from the electronics area to get to the ceiling or other side of van go up the main frame just behind the galley, and I’ve not insulated that frame at all.

For the ribs that you do insulate, I think I would lean towards the Thinsulate. It pulls through the ribs pretty easily. The only down side I see for the Thinsulate is that it lets water vapor through to the van skin, but maybe OK for these limited areas.

Another approach for the ribs would be if you could get even some thin insulation adhered to the inside surface of the frames/ribs. The insulation is more effective if applied on the inside of the frames as it does not allow the metal frame to conduct heat around the insulation. A half inch of polyiso inside the frames would be very effective, but even a 1/4 inch of insulation inside the frames would be quite helpful.

https://www.buildagreenrv.com/insulating-thermal-bridges-due-metal-frames/

For the 2 inch thick wall insulation, you might have to experiment a bit figure out how to get it tight against the wall. With 1 inch thick, you can use the spring sticks to hold tight against the wall while the Great Stuff cures, but the 2 inch may be too stiff for that to work. Maybe 2 layers of 1 inch? or, cut some saw kerfs part way through the 2 inch polyiso on the outboard side? Or, maybe its not a problem at all 🙂

I’d like to hear how the 2 inch polyiso comes out.

Gary

Gary,

Thanks for the quick response. I also don’t see much downside to Thinsulate except that it is outrageously expensive. And that is a huge downside.

As far as the 2″ polyiso I glued 2 panels to the van with Loctite. Seems to work well. I plan to cover the edges of the insulation with Great Stuff to keep moisture from getting behind.

I don’t know what spring sticks are and I plan on just using Great Stuff to adhere the rest of the polyiso. Is there an issue if the polyiso isn’t touching the wall and only the great stuff is? It seems like that would be the case with 1″ or 2″ either way?

Thanks again

Hi Kevin,

By spring sticks I mean the sticks used to hold the polyiso against the van skin while the Great Stuff is curing — you can see some of them in the pictures above.

I do think its good to have the polyiso held against the van skin while the Great Stuff is curing just to make sure there is a good bond and to minimize any chance of water vapor getting behind the polyiso. I like the idea of using enough Great Stuff so that it completely fills any narrow gaps between the polyios and van skin. The photo above that shows the polyiso with a full grid of Great Stuff applied looks good to me.

Gary

Hey Gary, just wanted to drop a line and say thank you for being such a great resource! I ended up going the polyiso route. I used 3M adhesive spray on the back to hold it in place and great stuff pro around the edges. Thanks!

https://cascadelines.com/2017/10/03/ram-promaster-floor-insulation/

Hi Erik,

Nice job on the website — hope you keep adding to it.

Gary

Thanks Gary, that’s the plan! Hoping it can be an informative resource for others, like yours is.

Erik

Appreciation to my father who told me regarding this blog, this

weblog is truly awesome.

Thanks!

Gary

Hi Gary, I am leaning towards polyiso boards. Still waiting for van delivery so detailed measurements not yet possible to better know what board thicknesses to plan on.

My question is on reflective surfaces in a limited wall assembly. Insulation is simple, it works in either direction, heat travelling outward (winter) and inward (summer). However, implementing a reflective surface seems to work best in one direction. I have decided to reflect radiant light back towards van wall (summer mode) as I rather keep van cool without air conditioning. This is similar to what people do in their attics, bouncing radiant light back to the roof keeping the attic cooler. Am I missing something when applied to a van?

Assuming you agree with my plan, I will need to glue the polyiso boards say 3/4″ away from bare van wall with spacers? or ? With this system the van wall is wide open to condensation when weather cools down. When this happens I expect condensate to run down headed to weep holes and/or evaporate. I will not top this assembly with a vapor barrier by the way.

Speaking of condensation running down to weep holes, from photos I can not see a clear path for that to occur, specially from the ceiling. Where would ceiling condensate run to ?

Thanks Gary

Santiago

Hi Santiago,

Recognize you from the PM forum.